Geosynthetics for Railway Infrastructure

The Geofabrics Rail Division has critical design expertise and a long project history in the utilisation of geosynthetics for the construction and maintenance of rail formations.

We offer a range of solutions for new track construction as well as renewal or maintenance of existing railway tracks which can deliver both construction savings and life-cycle optimisation.

- Improved bearing capacity of in situ subgrades to enable formation construction

- Improved structural performance of ballast and reduced soil importation

- Extended maintenance intervals and reduced costs by maintaining track alignment

APPLICATIONS

Mud Pumping

Mud pumping can result in loss of line and level and the creation of mud holes which have traditionally required extensive maintenance and monitoring to keep under control.

Tracktex Green geocomposite has been developed to address the extensive and expensive track and ballast deterioration problems caused by mud pumping. When installed at the ballast formation interface, it prevents rain water penetrating through to the underlying deposits while under load, allowing a controlled upward movement of water through capillary action and also filtering and retaining any fine soil particles, in situ, during the process.

It is a proven mud pumping solution which has been used to deliver significant reductions in maintenance cycles on affected sections of track. In fact, Tracktex Green increases track bed maintenance intervals on sections affected by pumping failure by more than 25 times, providing significant savings over any available alternative.

Track Ballast Stabilisation

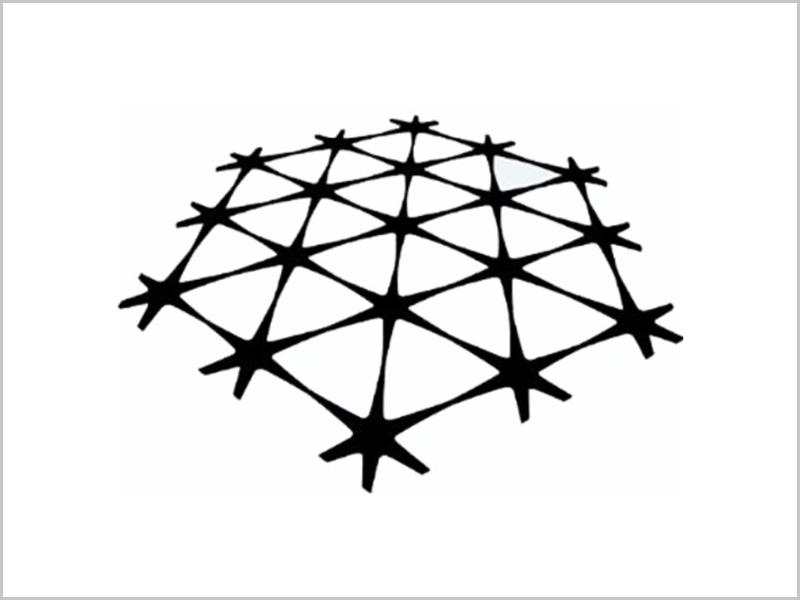

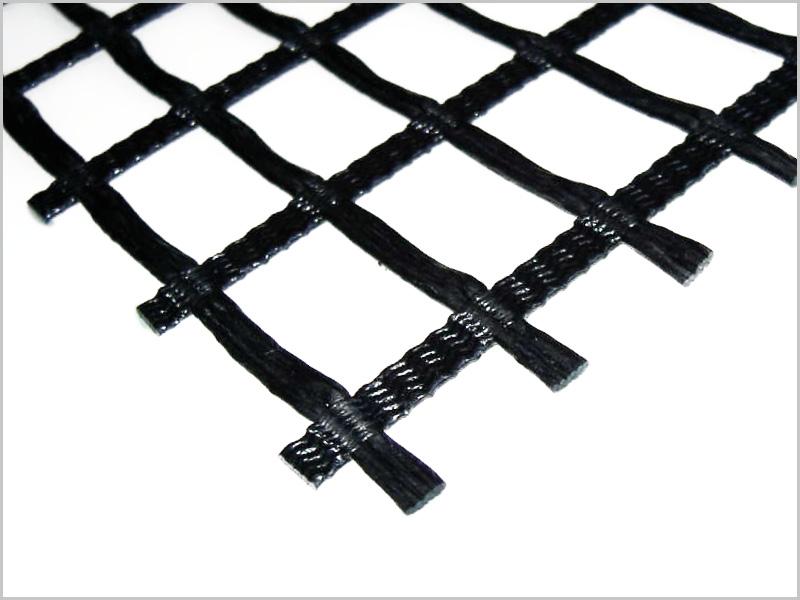

Approved by national rail authorities around the world, Tensar TriAx TX190L geogrid is specifically designed for use in track beds. The unique large aperture triaxial structure of Tensar TriAx is designed specifically for track ballast stabilisation and is scientifically proven to lock ballast in place limiting lateral movement and keeping tracks aligned. This technology reduces the rate of ballast degradation and settlement to extend the track maintenance cycle. Using geogrids reduces the amount of foundation material required by up to 30%, which in turn, reduces construction costs.

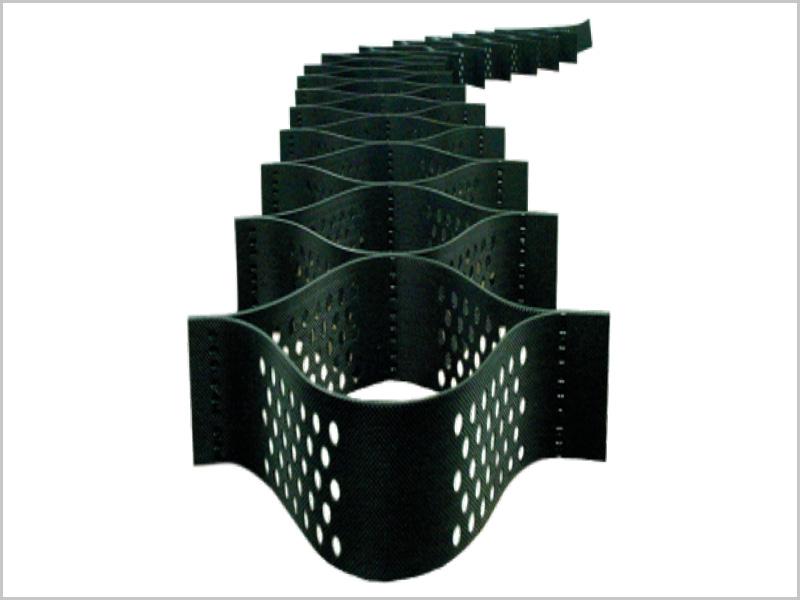

Presto Geoweb can also help create high-stiffness ballast layers by confining the ballast within the 3D structure, creating a stiffened slab which increases load bearing capacity and minimises horizontal and vertical movement. The perforated structure of Geoweb geocell allows lateral drainage of water from within the ballast.

Subsoil Drainage

Bearing capacity of foundation material below ballast is affected by excess moisture unless effective subsurface drainage is in place. Megaflo Green panel drains have a profile that offers a higher resistance to deformation and loss in discharge capacity required for use under rail track. It is a proven quick response drainage solution widely used across Australasia to remove water from rail track formations.

Ground & Pavement Stabilisation

Tensar TriAx geogrids are used within the track substructure by improving the track foundation through the mechanical stabilisation of the capping layer. When constructing track over soft subgrade soils having a low bearing capacity, it is necessary to improve the foundation to support the ballast effectively. Capping layers reinforced with Tensar TriAx geogrids can increase load carrying capacity and prolong service life. Using geogrids also decreases the amount of capping layer material required by up to 30%, which in turn reduces construction costs. Incorporating Tensar geogrids means less excavation and fill material is needed.

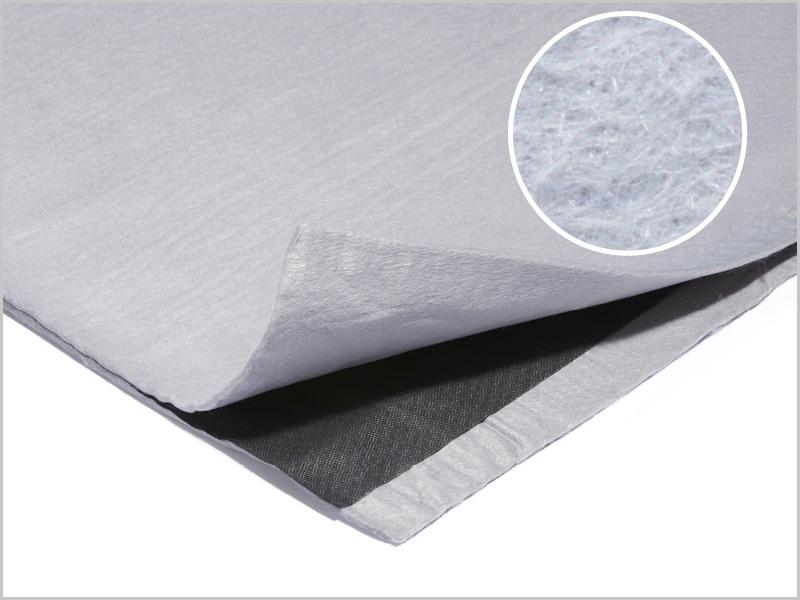

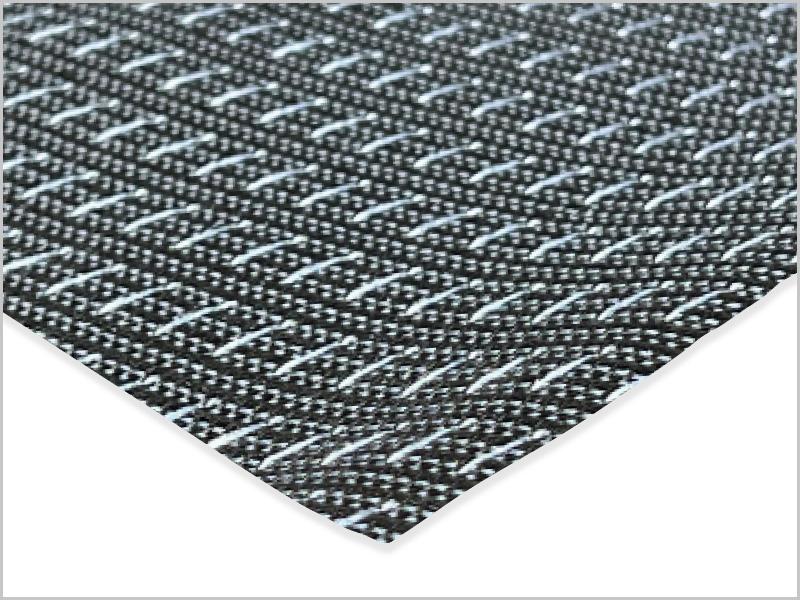

The addition of Bidim Green non-woven geotextiles between the capping layer and the subgrade provides separation and filtration, enhancing the effectiveness of track drainage reducing the softening of the capping layer.

Our Presto Geoweb geocells are a proven technology for solving challenging soil stabilisation problems common in the railroad industry, across the globe. Railway engineers have successfully applied Geoweb to provide a high-stiffness roadbed foundation at grade under track, crossings and turnouts, particularly in areas of weak soils. It stabilises the capping layer, reducing vertical and lateral stresses and significantly reducing subsoil movement, resulting in significant long term performance improvement and a reduction in the amount of foundation material required by up to 50%.

Flood Protection

Floods cannot be prevented but can be managed with Maccaferri FlexMac, a lightweight and flexible unit made of hexagonal double-twisted wire mesh, that is reinforced with steel rods and internally lined with a non-woven geotextile. The units are filled with available materials such as sand and gravel, to create a longitudinally safety barrier around critical infrastructure.

For flood mitigation and control, FlexMac is 40 times faster to construct than traditional sandbags; enabling quick response times and rapid deployment in emergency situations. It can provide a temporary barrier to protect critical infrastructure such as railway lines which provides access to flood prone areas.

Erosion & Sediment Control

Erosion control mats are categorised as either biodegradable, made from 100% natural fibres that are often applied as a temporary cover; or are non-biodegradable, made from synthetic fibres to provide permanent coverage. They primarily differ in the material used as well as the thickness of the mat and its relevant applications.

The overall aim in using geosynthetics in erosion control is to maintain soil cover either as a temporary measure offering protection from soil loss while vegetation is established or as a permanent control measure, typically on steeper slopes that run along the railway track.