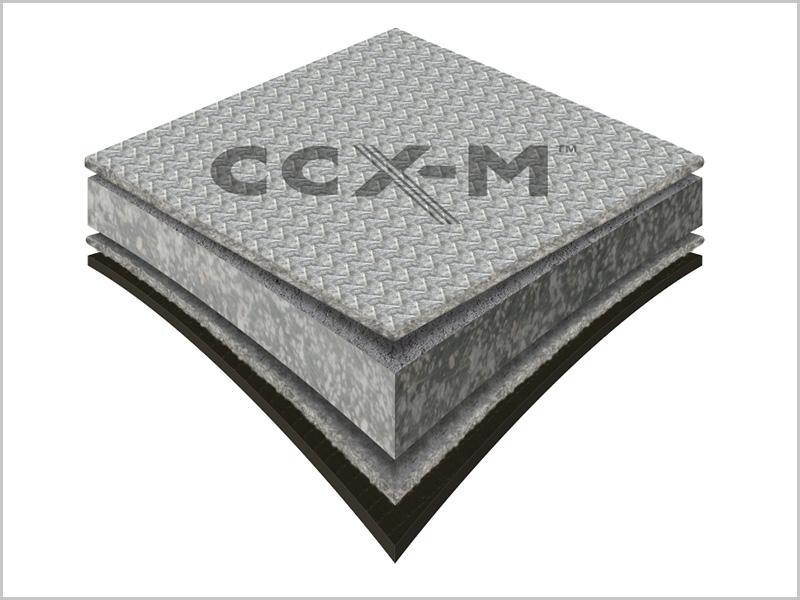

Concrete Canvas® geosynthetic composite cementitious mat (GCCM) is a flexible, concrete impregnated fabric that hardens when hydrated to form a thin, durable, water proof and fire resistant concrete layer.

It is used for a wide range of erosion control and weed suppression applications, and allows concrete construction with minimal plant and specialist training.

Typically ten-times faster to install than conventional solutions, essentially its Concrete on a Roll™: simply unroll and just add water.

Installation is easy as it allows concrete construction without the need for plant or mixing equipment. Simply unroll, position and add water (any type of water, including sea water).

To ensure long-term performance of a GCCM and prevent premature failure, a new standard known as ASTM D8364 has been published which requires minimum performance values to be met for a product to be considered a GCCM.

Concrete Canvas is the world’s first patented GCCM that meets ASTM D8364 – Standard Specification for GCCM Materials and exceeds the requirements for Type I, Type II and Type III applications.

WHY CHOOSE CONCRETE CANVAS?

- Rapid installation as Concrete Canvas can be laid at a rate of 200m²/hour by a three-person team where typical installation speeds are up to 10 times faster than conventional concrete solutions

- Easy to use with portable rolls available, reducing the need for equipment on site and allowing concrete installation in areas with limited access. Prior to hydration, Concrete Canvas layers can be cut to length using basic hand tools eliminating the hazards associated with using power tools in high risk environments. The concrete is pre-mixed so there is no need for mixing, measuring or compacting – just add water

- Lowers project costs due to the speed and ease of installation which means Concrete Canvas is more cost-effective than conventional concrete, with less logistical burden. Up to 200m² of Concrete Canvas can be supplied on a single pallet, greatly reducing transportation logistics and on site storage

- Eco-friendly solution with a low mass, lower carbon technology which uses up to 95% less material than conventional concrete. A single pallet of CC can cover the same area as two 17T mixer trucks for many applications

- It is five-times as abrasion resistant as standard OPC concrete, has excellent chemical resistance, good weathering performance and will not degrade in UV

- Incorporates strong fibre reinforcement which prevents cracking, absorbs energy from impact and provides a stable failure mode

- Provides more than 60% CO2e saving compared to conventional concrete solutions for erosion control applications in the UK. Calculate carbon savings for your next project here

- BBA (British Board of Agrément) certified with a durability in excess of 120 years when used in erosion control application

APPLICATIONS

Hydraulic Engineering & Structures

Channel & Ditch Lining

Concrete Canvas is rapidly becoming the channel and ditch lining material of choice for engineers and contractors around the world. This product solution provides a hard-wearing erosion control surface for lining drainage and irrigation channels. Concrete Canvas is typically used as an alternative to conventional concrete drainage and where vegetated or earth lined ditches are unsuitable due to high flow rates, containment requirements or the need to reduce maintenance.

Concrete Canvas is significantly faster, easier and less expensive to install than conventional concrete channel lining and requires no specialist equipment. The matting can be laid at a rate of 200m² per hour by a 3 person team.

Culvert Lining

Concrete Canvas can be used to extend the durability of new culverts and upgrade existing structures by relining steel and concrete culverts, which have degraded due to scour and corrosion. This prevents the need for asset replacement and extends the life of culverts with improved impermeability and flow characteristics.

Outfalls

Concrete Canvas has been used worldwide as an effective method of preventing surface erosion and scour associated with water run-off from culverts outlets, spillways and over-toppings.

Erosion & Sediment Control

Slope Protection

Concrete Canvas is increasingly being used as an alternative to non-structural shotcrete to protect slopes from surface erosion caused by weathering, surface run-off and environmental degradation. In certain applications Concrete Canvas can be used as structural slope stabilisation by combining it with steel mesh and soils nails.

Compared to shotcrete it is typically faster to install, more cost effective, requires less specialist plant equipment, and eliminates the risks associated with rebound and debris.

Bund Lining

Concrete Canvas can be used for hard armour capping of earth bunds around petrochemical tank farms, munitions depots and flood defences. It is typically used to protect the bund from environmental degradation, animal damage improve impermeability and prevent weed growth.

Concrete Canvas ability to be installed quickly reduces time on site. The installation speed for bund lining is approximately 800 m2/day with a 6-man crew. Concrete Canvas Hydro may also be used in this application.

Vent Walls

Concrete Canvas can be used as an alternative to brattice cloth, plaster board or concrete block-work to construct blast and vent wall structures for underground mining applications. Trials have shown that Concrete Canvas typically provides cost savings of over 20% compared to conventional solutions.