BIDIM C LINING ENABLES EFFECTIVE LEAK DETECTION AT SA MINE

PROJECT DESCRIPTION

Located in South Australia, this mine site had aggressive wastewater that needed to be contained. Geofabrics was approached by Fabtech to assist with providing geosynthetics for constructing an effective lining system.

OUR SOLUTION

A robust design was completed by installing a CSPE primary liner over the Bidim A34C conductive non-woven geotextile and geocomposite drainage layer. Achieving zero hydrostatic head on the compacted clay layer secondary liner provided further protection.

While the primary liner leakage rate was designed to allow for state of practice seepage rates with an additional factor of safety, the target commissioning seepage rate was close to zero. To achieve the target seepage rates, an electrical liner integrity survey was performed. A conductive material was required below the CSPE primary liner membrane layer to ensure an accurate survey.

Geofabrics was chosen to provide the geotextile between the geocomposite drainage layer and CSPE primary liner, as well as the cushion layer. The Bidim A34C geotextile is highly conductive so that the installer can conduct a leak detection study on the CSPE liner.

Design and construction works were completed by Fabtech who installed a high-quality storage asset with an assured commissioning process, avoiding risk or delays when handing the asset over to the operational department at the mine.

PRODUCT USED

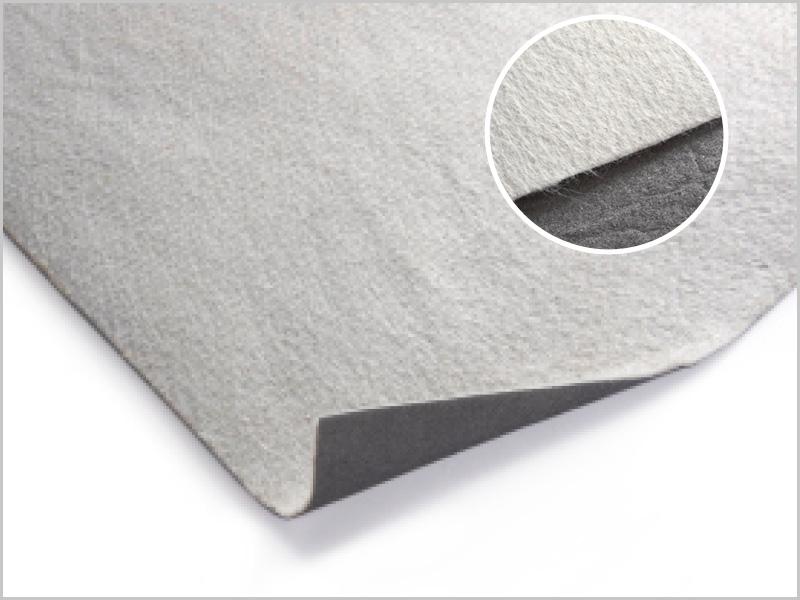

Bidim® C Conductive Non-Woven Geotextile

- A strong three-dimensional structure with high elongation, providing excellent filtration and acts as a cushion to subgrade

- Effective and economical leak detection surveys for geomembrane lining systems using Arc testing for holes and defects as small as 0.2mm

- Durable with a high melting point and high UV resistance due to Bidim polyester properties

- Simple installation with no heavy machinery, equipment or special skills required