- Home

- News & Insights

- Benefits of Using Geosynthetics in Railway Lines - Turnouts

Whole of life cost on rail track has become increasingly important as rail asset owners and operators look for ways to maximise their maintenance budgets whilst maintaining safety and serviceability.

An independent life cycle cost analysis conducted by industry leading cost engineers, WT Partnership, has shown that geosynthetics can significantly reduce whole of life costs when compared to traditional track formations and construction methods.

WT Partnership’s report, Track Formation Rehabilitation Options (Geofabrics) – Cost Options and Whole of Life Comparisons (June 2016), was carried out comparing a range of different scenarios using Geosynthetics and comparing them to conventional track formation practices which do not utilise Geosynthetic solutions.

The study investigated a 200 metre long section of track renewal over a 40 year life span and made conservative assumptions around total replacement costs. The study investigated three capital works life span replacement intervals: 15, 20 and 25 years. These intervals can be considered conservative as geosynthetics have proven to contribute to the performance of rail lines for intervals in excess of these time frames.

When constructing track over soft subgrade soils having a low bearing capacity, the foundation layers can be reduced or improved by the inclusion of a Tensar TriAx® geogrid. Introducing a Tensar® mechanically stabilised layer using TriAx® geogrids, enables a significant reduction of capping layer thickness for the same bearing capacity or alternatively can offer a significant increase in bearing capacity for the same capping layer thickness.

This can result in a reduction of subgrade excavation, spoil disposal, less imported capping layer fill and improved performance, while still achieving the target stiffness value required for the support of the ballast. Tensar® geogrids have extensive experience in mechanically stabilising capping layers, throughout Australian railway corridors that has resulted in many successful cost-effective installations.

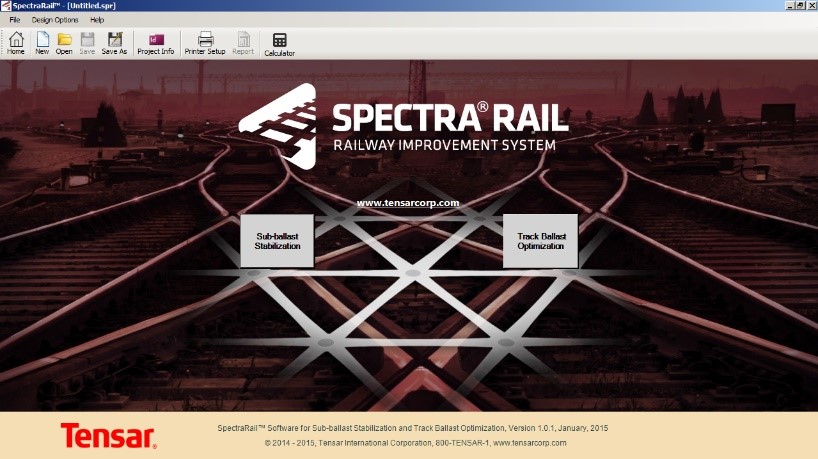

Tensar® has developed the Spectra® Rail Software which provides geotechnical engineers the most powerful tool available for evaluating design options and optimizing railway systems using Tensar® Geogrids. Developed specifically for Tensar® Spectra® Rail Railway Improvement System, the software enables users to evaluate and compare designs for both unstabilized and mechanically stabilized rail roadbeds with a comprehensive cost analysis for each alternative.

The Spectra® Rail Software has been developed by Tensar® to include trackbed design sections in full compliance with AREMA (American Railway Engineering and Maintenance of Way Association) guidelines. Click here to request access to the SpectraRail software

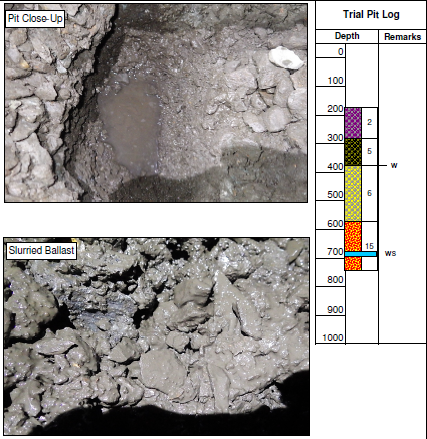

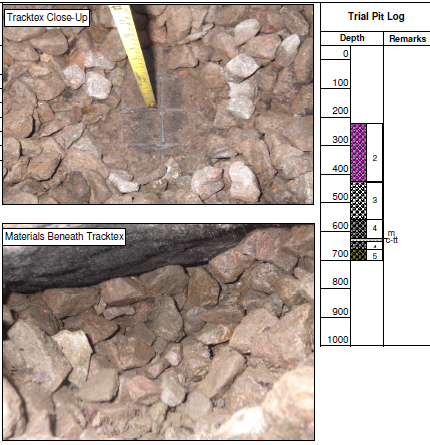

An independent report on mud pumping in a rail line was carried in February 2017 at a trial site location at Bradley Junction, UK. This report considered a 6 year performance of Tracktex® Anti-pumping Geocomposite to prevent mud pumping and compared it to the performance of an adjacent control section. Photos below in Fig 2 and Fig 3 clearly highlight the performance of Tracktex® to prevent mud pumping. The advantage of using Tracktex® in a turnout is its added ability to prevent water ingress through the ballast layers into the capping layer below. Preventing over saturation of the capping layer will prolong the service life which in turn prevents costly turnout maintenance.

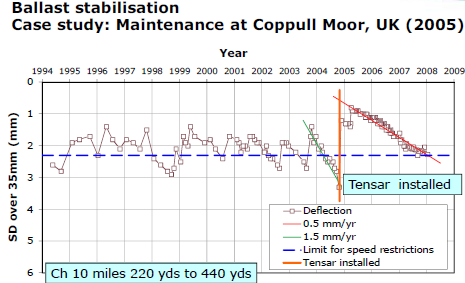

As Geosynthetics have also proven to increase the maintenance cycles of rail lines a further assumption has been made in respect to tamping operations. The study considered tamping on a yearly basis for the control sections and at three yearly intervals for the Geosynthetic sections. This is also considered conservative as Fig 3 Maintenance at Coppull Moor, shows a greater than three times improvement to tamping cycles.

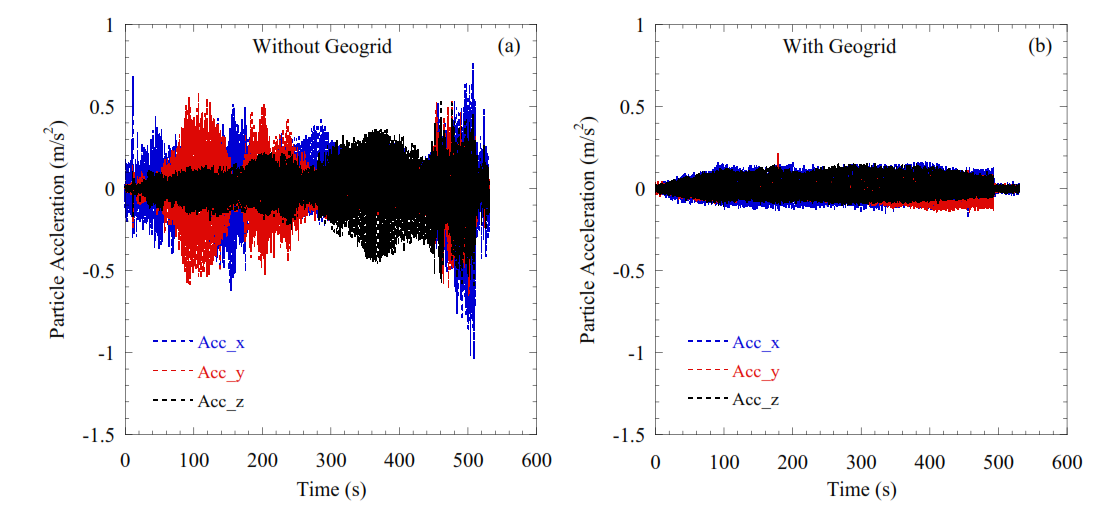

Further to the Coppull Moor trial, the use of ballast geogrids are further enhanced by a study conducted at Penn State University by the inclusion of a Smartrock into a test bed. Fig 5 shows the translational movement of ballast in a track bed with and without Tensar® TX190L geogrid.

WT Partnership’s report, shows that over a 40 year period the use of Tracktex® and Tensar® Geogrids in combination for a track turnout renewal could potentially save >$2M in ongoing maintenance costs.

DOWNLOAD THIS TECH NOTE (INCLUDES CROSS SECTION)

Related News

Related Products

Related Sectors

KEEP UP TO DATE WITH THE LATEST FROM

GEOFABRICS BY SUBSCRIBING TO OUR NEWSLETTER

GEOFABRICS

AUSTRALASIA

PTY LTD