- Home

- News & Insights

- Cost Benefits of Using Geosynthetics in Rail Level Crossings

Whole of life cost on rail track has become increasingly important as rail asset owners and operators look for ways to maximise their maintenance budgets whilst maintaining safety and serviceability.

An independent life cycle cost analysis conducted by industry leading cost engineers, WT Partnership, has shown that geosynthetics can significantly reduce whole of life costs when compared to traditional track formations and construction methods.

WT Partnership’s report, Track Formation Rehabilitation Options (Geofabrics) – Cost Options and Whole of Life Comparisons (June 2016), was carried out comparing a range of different scenarios using Geosynthetics and comparing them to conventional track formation practices which do not utilise Geosynthetic solutions.

At Open Level Crossings, rail tracks experience high impact loads from both road and rail vehicles and there is also a high impact zone where the rail vehicles transition from the “stiff” asphalt surface onto a ballasted “flexible” formation. Both the actual roadway and the transition zone are high maintenance areas where “mud-pumping” and vertical deflections are common. Rail authorities utilise various methods of controlling these problems including the use of the Geoweb Cellular Confinement system, Tracktex and Tensar TX190L.

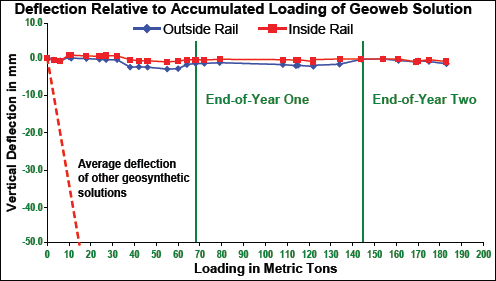

The Geoweb system is selected based on 30 years of rail industry use and independent testing conducted in 1998 at AAR FAST High Tonnage Loop in Pueblo, Colorado, USA. The testing examined soft sub grade solutions for tracks subjected to heavy loads and determined that the Geoweb load support system significantly improves load distribution, therefore reducing the vertical stresses reaching the sub grade. The system’s three-dimensional structure performs like a semi-rigid slab.

The Geoweb system is selected based on 30 years of rail industry use and independent testing conducted in 1998 at AAR FAST High Tonnage Loop in Pueblo, Colorado, USA. The testing examined soft sub grade solutions for tracks subjected to heavy loads and determined that the Geoweb load support system significantly improves load distribution, therefore reducing the vertical stresses reaching the sub grade. The system’s three-dimensional structure performs like a semi-rigid slab.

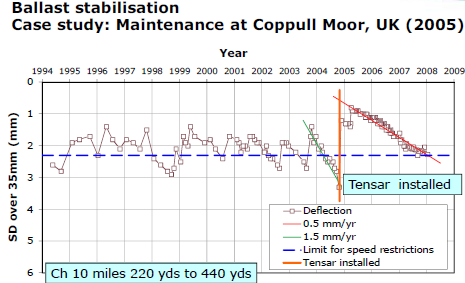

Further transitioning from the end of the Geoweb section can be achieved with Tensar TX190L Ballast Geogrid as was proven by a trial in the UK in 2005. Figure 1 Maintenance at Coppull Moor, shows the benefits that can be achieved by the inclusion of a ballast geogrid which provides a greater than three times improvement to tamping cycles. The use of ballast geogrids are further enhanced by a study conducted a Penn State University by the inclusion of a Smartrock into a test bed.

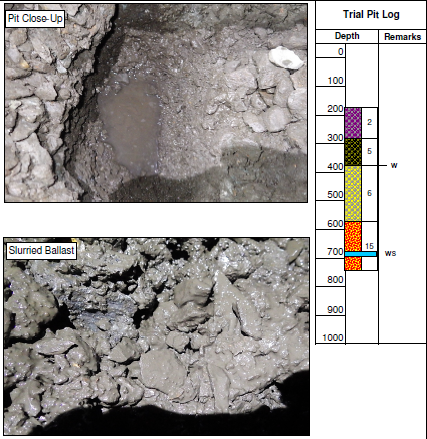

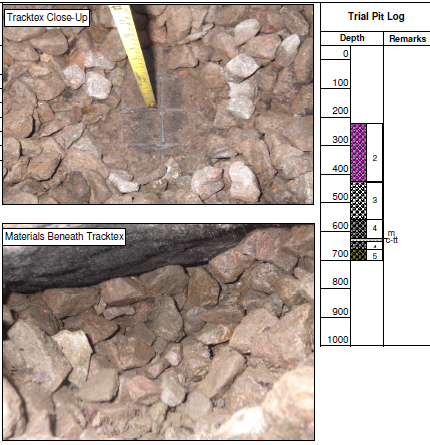

An independent report on mud pumping in a rail line was carried out in February 2017 at a trial site location at Bradley Junction, UK. This report considered a 6 year performance of Tracktex to prevent mud pumping and compared it to the performance of an adjacent control section. Photos below clearly highlight the performance of Tracktex to prevent mud pumping.

The WT Partnership study showed that over a 40 year period the use of a Geoweb, Tracktex and Tensar 190L geogrid combination for a track renewal could potentially save $19.85 million per km in ongoing maintenance costs.

Download This Tech Note (includes cross section)

Related News

Related Products

Related Sectors

KEEP UP TO DATE WITH THE LATEST FROM

GEOFABRICS BY SUBSCRIBING TO OUR NEWSLETTER

GEOFABRICS

AUSTRALASIA

PTY LTD