- Home

- News & Insights

- Reusing Fouled Ballast with the Aid of Tensar TriAx

Fouled or contaminated railway ballast is material recovered from the formation containing broken ballast particles, soil fines and other contaminants deposited during normal rail operations. The disposal of this material is an issue for many rail authorities as it may contain hazardous hydrocarbon compounds and is a heavy, expensive material to cart to landfill. Therefore, if fouled ballast could be reused or recycled in other parts of the rail formation, such as in a capping layer, this would provide a cost-effective solution to this issue. The use of an effective stabilisation geogrid in combination with the fouled ballast capping layer could assist in strengthening the material.

Methodology

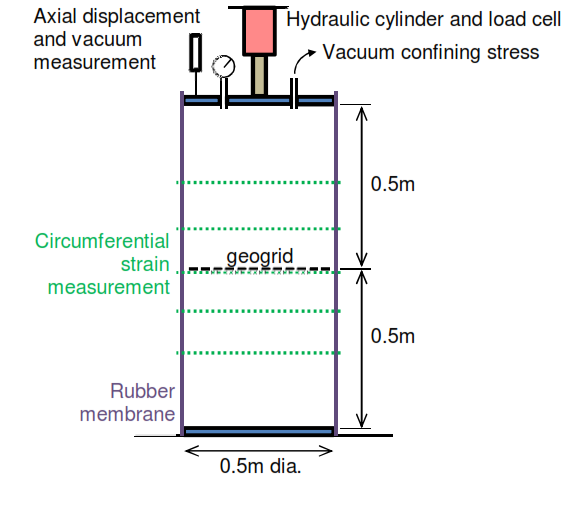

Tensar was approached to investigate the performance of fouled ballast with two grades of TriAx stabilisation geogrid, TX170 and TX190L for a large rail authority. Testing was performed using a very large triaxial compression cell (500 mm dia, 1,000mm height), with the geogrids placed at the mid-height of the specimen, the test set-up is shown in Figure 1.

Figure 1-Test set-up

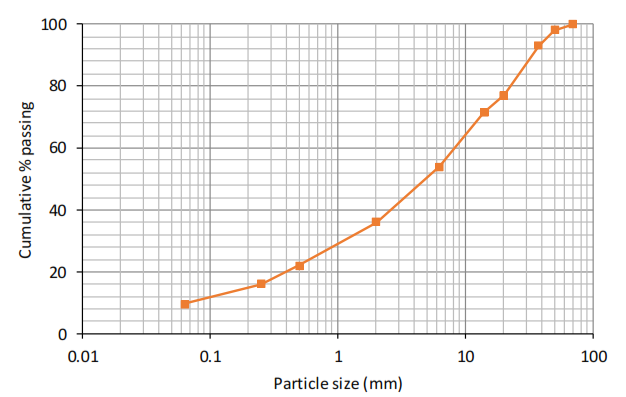

As the testing was conducted outside Australia, the fouled ballast material was replicated locally using a crushed diabase rock, and the grading is shown in Figure 2.

Figure 2-Particle size distribution of fouled ballast material

Confining pressures between 10 and 75 kPa were applied to the specimens which were compressed axially with axial displacement, force and circumferential strain recorded.

Conclusions

The test results showed that the addition of Tensar TX170 or TX190L TriAx geogrid significantly increased the peak shear strength of the material. Furthermore, the enhanced strength was maintained to a higher axial strain level of about 10% compared with about 5% without geogrid.

Consequently, the addition of TX170 or TX190L to a similar fouled ballast material would be expected to result in significantly reduced permanent deformation under repeated traffic load compared with application of the same material without TriAx stabilisation.

The performance of the TX170 and TX190L products were quite similar although at low confining stress (about 10kPa) the TX190L provided greater shear strength. Therefore, at low confinement depths of about 0.5m the TX190L is likely to provide further improved performance compared with the TX170.

NOTE: The results and conclusions contained herein are relevant to soil types similar to the material grading in Figure 2 above.

A summary of the results is shown below in Table 1 - Summary of TriAx peformance below.

|

Confining Pressure (kPa) |

Height of Material above grid (m)* |

TriAx Grade |

|

|

TX170 |

TX190L |

||

|

10 |

0.5 |

~ |

Yes |

|

43 |

2.15 |

Yes |

Yes |

|

75 |

3.75 |

Yes |

Yes |

* Assuming material density of 20kN/m

Related News

Related Products

Related Sectors

KEEP UP TO DATE WITH THE LATEST FROM

GEOFABRICS BY SUBSCRIBING TO OUR NEWSLETTER

GEOFABRICS

AUSTRALASIA

PTY LTD