- Home

- News & Insights

- Specifying Cushion Geotextiles

Hydraulic Values for Geomembranes

Polyethylene geomembranes are used in dams, landfills and tailings dams as the primary hydraulic barrier to separate contaminants from groundwater. Logic would suggest liner design would therefore include hydraulic or permeability values for these products, but these are not seen in project specifications. The explanation is that if you ensure that the geomembrane PE formulation meets site conditions, and ensure that certain basic mechanical properties are met with emphasis on thickness (1.5–2.0 mm+), then permeability through the liner can be assumed to be extremely low. It is design analysis of potential holes and liner stress post placement that determines hydraulic performance and good design requires an understanding of these potential damage mechanisms.

Damage Mechanisms

In the past geomembrane damage was directly linked to the quality of the welding process during installation. In recent times, with the introduction of independent auditors, damage is far more likely to be caused during placement of angular drainage aggregates above. To reduce this risk, cushion geotextile is the single design element to ensure that aggregate point loads do not impart unacceptable strains to the geomembrane. Failure to design correctly leads to construction damage and increased liner stress cracking long term.

History of Cushion Geotextile Design

Like all geotextiles, the underlying design aim has been to develop a table of test methods and required values that could be transferred from site to site. A historic review of cushion geotextile design illustrates the difficulty in trying to establish both a suitable test regime, and specification test methods or values that are relevant.

Specifying by Mass

Initial attempts were made to define cushion performance by geotextile mass. This option has been critiqued by many studies that have shown that polymer/fibre type/fibre blend and manufacturing technique all can show markedly different performance for the same fabric mass. In fact, a high mass geotextile with low mechanical strength is the single biggest indicator of poor manufacturing technique.

Specifying Test Methods and Values

Once mass is dispelled, what mechanical properties are critical to specify and what tests demonstrate them?

GRI GT12

One of the more often represented benchmarks are the GRI GT12 Guidelines. This includes a range of technical parameters for: mass, grab, trapezoidal tear strength, and puncture and provides a greater representation of overall geotextile mechanical properties. The fundamental question is do these tests capture geotextile cushion performance? The answer is we don’t know, because different manufacturing techniques represent each parameter differently. This is readily observed for puncture and CBR strength, test methods attempting to replicate aggregate being pushed into the fabric. Research shows a correlation for specific polymers and manufacturing sources but no cross correlation across geotextile types.

What is further evident is the GRI GT12 numbers seem low as a representation of current geotextiles. These values were certainly relevant for the time but are becoming obsolete as manufacturing techniques have improved. It seems counter intuitive to think that a designer would want to limit their factor of safety by using this table when current manufactured options will perform better.

What is The Key Specification Parameter?

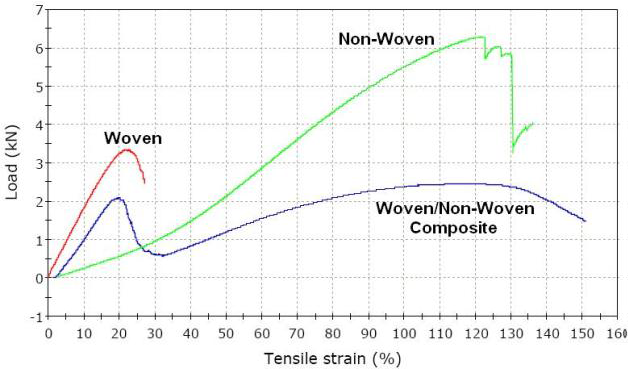

I wish I knew, unfortunately there is no key parameter that represents different geotextiles and their cushion behaviour. Geofabrics now includes wide strip toughness in bidim specifications but this still has certain limitations. I can analyse the area under the graph in a stress/strain curve and get a correlation between tensile strength and elongation for a thin woven geotextile but this product doesn’t have the thickness and CBR resistance for direct impact. Our Texcel nonwoven staple fibre geotextiles have excellent elongation properties but do not perform as well in testing mass for mass with our bidim continuous filament geotextiles.

An understanding of the Site Aggregate and Geomembrane likely through project specific testing is really the only method to establish the relevant parameters.

Performance Testing

It is well established that cushion testing results will vary according to the depth of the landfill cell and subsequent normal stress, but less well known that specific site parameters are critical. Specified Geomembrane thickness, quality and texture define liner behaviour, but particularly critical is the angularity and particle distribution of the aggregate. The testing regime must be replicable, and the strain measurement technique must be on a finite scale. It is localised stone point loads that need to be measured and will drive performance.

It is spurious to suggest that strain limitations on the geomembrane should be kept to under 0.25-1% if a method to ensure testing replicability is not carried out, and finite analysis not conducted. The best test methods to develop empiricism should have the ability to replicate the test with the same aggregate and liner, and apply factors of conservatism to account for the subgrade and aggregate variability. I suspect the methods used in Australia and specified in the current Victorian and NSW EPA Landfill Guidelines are the most suitable.

How Can I Specify?

My suggestion for specification is to put a table of cushion geotextile values for pre-qualification. A table can be sourced from manufacturer’s datasheets tested previously, or the GRI GT12 Guidelines (that may underestimate current geotextile capabilities). Design expertise will be required to ensure this nominated product is similar to the product that will pass specific testing for the site.

Designers with an extensive library of results can lean on their database, but there is also the option for the client to conduct performance testing during the design process, with an added benefit to explore the economics of various drainage aggregates, geotextiles and geomembranes.

Client Costs

The key point is that the correct cushion geotextile specification is paramount to geomembrane longevity. Site specific testing is critical because it is extremely difficult to specify a range of parameters, but the asset owner should utilise the testing process to explore more economic sources of aggregate and geosynthetics, while lowering long term risk of leaks.

The views and opinions expressed in this article are those of the author and do not necessarily reflect the position of Geofabrics or other Geofabrics staff.

Related News

Related Products

Related Sectors

KEEP UP TO DATE WITH THE LATEST FROM

GEOFABRICS BY SUBSCRIBING TO OUR NEWSLETTER

GEOFABRICS

AUSTRALASIA

PTY LTD