- Home

- News & Insights

- Water Storage Pond

A $15 million upgrade to SA Water’s Morgan Water Treatment Plant was undertaken to help meet future demand and further enhance the quality of drinking water to more than 130,000 regional South Australians.

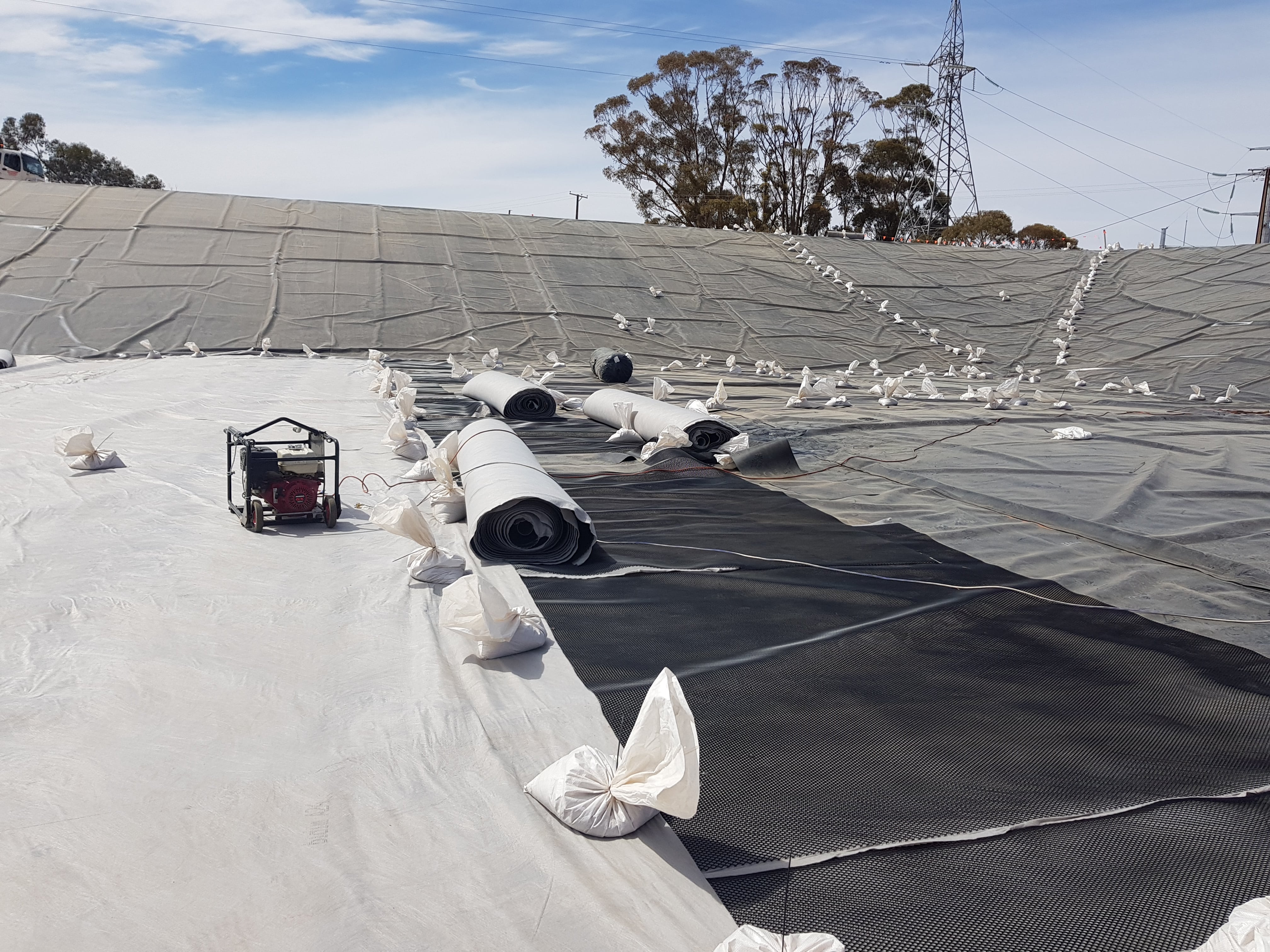

The upgrade included the construction of a 30 ML earth bank dam with the civil earthworks and construction carried out by Leed Engineering. Geotest was engaged as the lining contractor to install the various layers within the dam liner as well as test for any leaks within the sealed Oasis liner.

Geofabrics was chosen as the supplier of choice due to their proven Quality and Assurance, product durability and their reliability of supply across their broad product range.

The liner system comprised a series of Geofabrics supplied products which included (bottom to top):

- Drainage Layer: M5 Flownet with A14 Geotextile Laminated

- Cushion Layer: A64 Geotextile

- Secondary Liner

- Conductive Layer: bidim A19C

- 30 year Liner: Ethylene Interpolymer Alloy (EIA) Oasis 1.14 mm

- 30 year Floating Cover: EIA Oasis 1.5 mm

The M5 Flownet was chosen as a drainage blanket to enable any leakage or sub liner flows to be channeled towards the dam’s subsurface sump and gravity disposal pipe.

The cushion layer, A64 geotextile, was chosen due to its proven capability as a heavy cushion geotextile. Geofabrics’ Centre for Geosynthetic Research, Innovation and Development (GRID) has proven through extensive testing that A64 is ideal for cushioning liners in applications such as this one.

bidim C, a graphene coated conductive geotextile, was utilised to enable real time quality assurance testing for existing holes within the liner or welded joins. The process of spark testing can pick up pin holes not visible to the naked eye, and the conductive geotextile, bidim C improves this process as it is 100 times more conductive and effective than the previous method which comprised wetting up of the subgrade. Relying on an evenly wetted subgrade for conductivity and sparc testing can be difficult and should not be relied upon to ensure a current is evenly distributed below the liner. bidim C makes this process simple, effective, quick and safe.

The Oasis liner and floating cover consists of an Ethylene Interpolymer Alloy (EIA) and was chosen due to its 30-year design life, its unrivalled chlorine resistance and its ability to be stored for extensive periods (unlike its counterpart CSPE which has a specified shelf life). Furthermore, the installer confirmed it is extremely easy to weld and “looked great”, being tan in colour.

The head contractor, Leed Engineering, also expessed their appreciation to Geofabrics for supplying a product that was simple to install.

Geotest installed all the products without any hitches and were extremely pleased with their first use of the Oasis floating cover and liner. They are hoping for more projects with the product in the future, particularly SA Water projects with high concentrations of chlorine.

The storage pond is now commissioned and in use, suppling 130,000 regional homes with safe, clean drinking water for at least the next 30 years.

DOWNLOAD THE CASE STUDY

Related News

Related Products

Related Sectors

KEEP UP TO DATE WITH THE LATEST FROM

GEOFABRICS BY SUBSCRIBING TO OUR NEWSLETTER

GEOFABRICS

AUSTRALASIA

PTY LTD